Wheaton Sprague was hired by APG, Atlantic Plate Glass, to provide engineering and shop drawings for the insulated panel metal system for U.S. Air’s new terminal at the Philadelphia Airport, a nearly 800,000 s.f. building designed by internationally acclaimed Kohn Pedersen Fox Architects, New York.

The scope of the project included 250,000 s.f. of insulated panels and the backup structure for the building. The facade used steel tube, steel channels, aluminum channels, angles and metal studs for the backup structure, anchoring off structural beams, floor slabs, and masonry walls. The panels consisted of aluminum face in the front and back, with insulation between.

Wheaton Sprague was contracted to provide shop drawings and engineering of all of the foam insulated panels. Challenges on the project included multiple phases, design-build elements, change in contractors, and large costs.

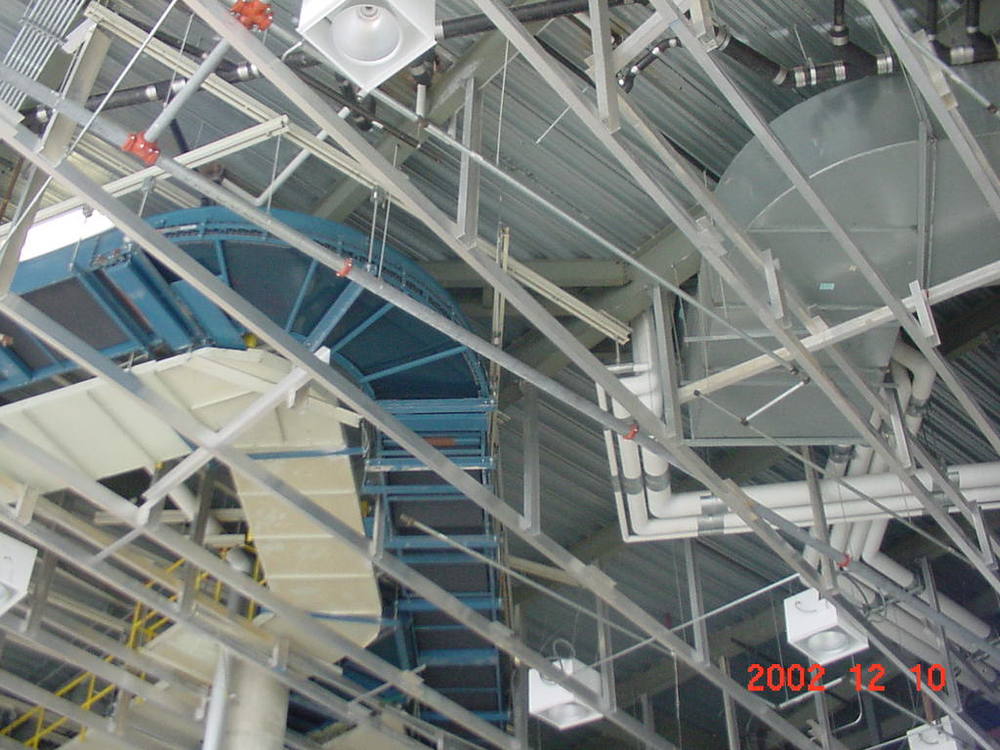

Engineering challenges included framing around the baggage belts. An associate with Wheaton Sprague used the Lindapter – a beam clamp that was in product development at the time of this project, and a prototype was able to be used to allow the person in the field the opportunity to manipulate and fine tune the location of the substructure.

Terminal A-West features 13 international boarding gates, more than 50 Bureau of Customs and Immigration inspection positions, 8 high-speed baggage carousels, 60 ticket counter positions, and a uniquely designed Arrivals Hall dominated by an atrium and stunning artwork conveying Philadelphia’s identity as America’s birthplace. The Terminal spans 190 feet over the approach roadway to accommodate complex programmatic needs.